Quality Module

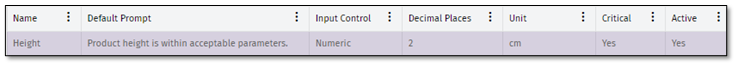

MESTEC 6.4 sees the introduction of the new quality module. Using this module, users can go paperless by creating checklists to capture all types of quality data including:

- Product variable measurements such as height and weight

- Attribute data such as count of defects

- Text data such as comments and serial numbers

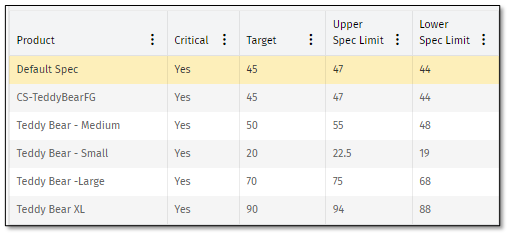

For each type of data it is possible to define individual specifications or acceptance criteria by product.

Checklists can then be referenced in product workflows allowing you to share one checklist definition across multiple products. During manufacture, operators are prompted to complete the appropriate checks using a shop-floor friendly user interface that supports touch screens and bar code scanners efficiently building up a detailed electronic batch history record (eDHR).

Check list items can be defined as requiring secondary approval and or electronic signatures. This capability along with robust change control and approval enables customers to meet demanding regulatory requirements.

Item Documents

We have expanded the capabilities of saving documents into MESTEC to include the ability to link documents to individual material items or lots. For instance, users can now save product photos or add a certificate of conformance.

New SAP Integrator

MESTEC is continuing to grow its collection of Integrators/Connectors. 6.4 sees the introduction of the MESTEC SAP Integrator, which provides a pre-developed set of interfaces for MESTEC interface developers to use to work with external SAP systems.

RCCP Capacity Charts – Budget vs Total Capacity

The rough-cut capacity planning charts give a comparison of the planned demand on resources and the planned capacity. 6.4 now allows for resources to be configured with budget efficiency, enabling RCCP charts to show both planned total capacity assuming 100% efficiency and budget capacity -- based on the configured budget efficiencies for each workcentre.

Partial Dispatch Reverse/Re-Receive

MESTEC 6.4 now allows users to perform a dispatch reverse. This feature supports both full and partial reversal of a pick operation.

New Shop-Floor Moves UI

Our new Shop-Floor Moves user interface allows users to explicitly plan, execute, and record the movement of WIP inventory. Shop Floor Moves can be easily configured between workstations following the completion of one operation and prior to the start of the next. The 6.4.0 enhancements now show Shop Floor Movers all WIP inventory pending collection or in transit by department and area.

The Shop-Floor Moves feature is listed in the Inventory menu group.

Users can also track Shop-Floor Moves Pending Collection and Shop-Floor Moves In Transit from their Workstation screen. Work orders pending a Shop-Floor move are tagged with a truck icon.

Setup is as easy as 1 click. In the workflow design tool, edit the flow between 2 operations. Then check the box to ‘Require explicit move.’ We’ve even added a tool tip!

Workstation Job Notes Indicators

The MESTEC Workstation has been enhanced with visual indicators to show which work items have job notes available and allows for them to be accessed directly via the Workstation home screen.

RestAPI Data Source Support

MESTEC can now pull data from external sources via RESTful APIs. This new capability allows for data from external systems to be pulled directly into MESTEC and influence on-screen controls such as graphs and charts to provide a truly integrated experience.

Raise Issue from Workstation

Users can now raise issues directly from the workstation.