1 Recipe version management

Our new Recipes feature provides a central link between products, Bill of Materials (BoM), and Workflows.

Flexible, configurable version control provides robust change management when required, such as in regulated environments like medical device, and aerospace and defense. However, it also provides the flexibility to minimise administration when strict control is not required.

Products can have multiple, concurrent recipes to support different methods of manufacture such as an option to sub-contract part of manufacturing. This simplifies job scheduling and ensures consistent build processes.

Workflow versions can now be shared between products, dramatically reducing configuration and administration effort when similar processes are common to many products such as non-conformance processing.

Recipe version management is supported by the introduction of BoM and Workflow versioning, and shared workflows.

1.1 BoM versioning

MESTEC now supports multiple Bill of Materials (BoMs) and versions for each product. This shift allows for greater control over product variations and changes.

Key elements related to BoM versioning are:

BoM Types and control levels

Bills of Material belong to a BoM Type which defines the degree of change control to be applied. Controlled BoMs provide stricter validation and require approval for changes, while non-controlled BoMs offer greater flexibility and reduced admin when strict control is not required.

BoM Types can also be configured to be “Job-specific” which creates a new version of a BoM for every job to support configured-to-order environments.

Major and Minor BoM Versions

BoMs have a major and minor version. Minor up-versions can be used to minimise approval admin where a change does not change the version of the finished good being produced or require an associated change to the workflow/recipe. For example, to add another alternate part number for a requirement on the BoM for an identical part from a new supplier.

Major versions can be used to enforce broader recipe and workflow approval for changes that change the version of the finished product or require broader changes to workflow. For example, to change a process to sub-contract an element of manufacturing would need a change to both BoMs and workflow.

Transferring items between BoM versions

Items can be transferred between different BoM versions to accommodate changes to design or process. This can be applied post-production or mid-production without the need to create new jobs.

BoM status and approval processes

BoMs may have the following statuses:

- Draft

- Pending Approval

- Approved

- Obsolete

BoM versions of a controlled type are created in draft status and then submitted for approval by changing to pending approval status. They must then be approved by a user with appropriate permissions which will change the status to approved before being used in production. Separate recipe approval may also be required. It is not possible to edit an approved version of a controlled BoM without creating a new BoM version.

BoM versions of a non-controlled type may be created directly in approved status (by a user with appropriate permissions) without the need for separate approval. Some changes are permitted to approved versions of non-controlled BoMs without up-versioning.

Obsolete status and job management

BoM versions can be set to obsolete status. This prevents the creation of new items based on an obsolete BoM version. However, existing items will continue to reference an obsolete BoM version and if in WIP, may be completed.

1.2 Workflow versioning

Workflow versioning has been enhanced in 7.3 to allow more strict revision control for regulated environments whilst allowing more flexible changes to reduce administration when strict control is not required.

Workflows no longer have a “temp” version containing pending changes which are then “published” to live when ready for production. Instead, changes are made to a new version, which is available to production when approved.

Key elements related to Workflows:

Workflow classes

There are three workflow classes: shared, template and product-specific.

Product-specific workflows are standard workflows that apply to a single product.

Shared workflows can be used for multiple products when they share common processes. This dramatically reduces the configuration and administration effort. A common use case for shared workflows is non-conformance or rework processes that are common to many parts. The products that a shared workflow applies to are defined by the recipes created/approved.

Template workflows serve as a base for creating product-specific workflows. New products can inherit a copy of template workflows without having to recreate it from scratch. This will create a product-specific workflow which can then be tailored to a particular product.

Workflow Types and control levels

Workflows belong to a Workflow Type which defines the class of the workflow and the degree of change control to be applied. Controlled workflows provide stricter validation and require approval for changes, while non-controlled workflows offer greater flexibility and reduced admin when strict control is not required.

Major and Minor Workflow Versions

Workflows have a major and minor version. Minor up-versions can be used to minimise approval admin where a change does not change the version of the finished good being produced or require an associated change to the BoM/recipe. For example, to update instruction text to improve clarity, without changing the method of manufacture.

Major versions can be used to enforce broader recipe and BoM approval for changes that change the version of the finished product or require broader changes to BoMs. For example, to change a process to sub-contract an element of manufacturing would need a change to both BoMs and workflow.

Approval processes

Workflows may have the following statuses:

- Draft

- Pending Approval

- Approved

- Obsolete

Workflow versions of a controlled type are created in draft status and then submitted for approval by changing to pending approval status. They must then be approved by a user with the appropriate permissions which will change the status to approved before being used in production. Separate recipe approval may also be required. It is not possible to edit an approved version of a controlled workflow without creating a new workflow version.

Workflow versions of a non-controlled type may be created directly in approved status (by a user with appropriate permissions) without the need for separate approval. Some changes are permitted to approved versions of non-controlled workflows without up-versioning.

Obsolete status and job management

Workflow versions can be set to obsolete status. This prevents the creation of new items based on an obsolete BoM version. However, existing items will continue to reference an obsolete BoM version and if in WIP may be completed. The obsolete status is equivalent to the previous “Approved – existing only” workflow status. The “Disabled” status had been deprecated: existing jobs will always be allowed to complete, even if the workflow status is changed to obsoleted mid-job. If live jobs must be stopped when a workflow is obsoleted then these jobs should be put on hold to prevent further work.

Shared workflows

Workflows of “shared” class can be referenced by multiple products. The products valid for a workflow are defined by the approved recipes that reference the workflow: see below.

1.3 Recipes

Recipes define a valid combination of a BoM version and a workflow version to be used in a job. While a BoM specifies the materials needed for a product and a workflow outlines the production steps, a Recipe ensures that these two elements are compatible.

Recipe statuses

Recipes can only be used in production when the BoM and the workflow are approved. Recipes can be in a draft, pending approval, approved or obsolete status.

Manage BoM and Workflow versions used in a Recipe

BoMs and workflows have major and minor version numbers, which helps differentiate between changes that are compatible with existing configuration (such as an update to workflow to clarify some instruction text) and changes that required more robust change approval (such as a change to a BoM to buy in a sub-assembly that requires an associated change to workflow).

When creating a Recipe, you can choose to:

- Specify a specific minor version of BoM and/or Workflow.

- Use the most recent version of a BoM and/or Workflow.

- Specify a specific major version of a BoM and/or Workflow, and automatically use its greatest approved minor versions. In this case, a new major version will not be used by the recipe.

Job creation and Recipe selection

Job creation now requires the selection of a recipe rather than just a workflow. Recipes are the new mechanism to connect a product to a specific BoM and workflow. This simplifies job scheduling and allows for different build configurations for the same product.

2 Integration Manager and Universal Connector

MESTEC version 7.3 has several enhancements to integration capabilities to make administration easier, minimise customisation and reduce the effort to implement new integrations. The improvements in 7.3 consist of:

- Improved administrative interface with the introduction of Integration Manager.

- Configurable triggers for outbound integration reducing the need for custom integration work.

- Standard RESTful APIs for common in-bound integrations.

- Integration Manager

The integration manager provides an administrative interface for all inbound and outbound integrations. New interfaces can be configured and logs for existing interfaces can be viewed.

2.1 Outbound integrations

Outbound integrations can easily be configured to send data to a third-party system when a defined trigger transaction occurs in MESTEC. Triggers initially supported are:

- Operation Start

- Operation Completion

- Workflow Creation

- Workflow Update

- Plan Update

- Job Status Change

- Scrap

- Asset Status Change

The integration can be configured to make a RESTful API call to a defined endpoint.

2.2 Inbound RESTful APIs

Inbound requests can be managed by calls to our public APIs which will reduce the need for custom solutions to process inbound data.

Supported APIs

The following APIs were upgraded in this release:

- Tools: Create and update tools.

- Work Centre: Create and update Work Centres.

- Product Create/Update: Create or update products, set product properties and clone a template product.

- Attendance Log: Clock a user in and out.

- Skills: Assign and unassign skills to a user.

API Documentation

You can explore the full list of supported APIs in the documentation at: https://dev730.mestec.net/apidocs/index

Improved human-readability

We have updated field names for request bodies and responses to be more human readable.

Improved permission control

To perform an action using the public API, you need to have the permissions set up in MESTEC for that action. For example, you are not allowed to create a product using the API unless you have the Product Administration permission.

Improved error messaging

Error messages provide specific information to help guide users to a resolution. For example, an error message could be: “The product type is not found.”

API versioning

API versioning was introduced to support backward compatibility and enable a smooth transition to the latest versions.

3 Translations

Version 7.3 extends MESTEC’s multi-language capabilities to display most elements of the web application text in the user's preferred language. This is in addition to supporting translations when printing product labels.

The languages initially supported are:

- UK English

- Danish

- Lithuanian

- Korean

- Belgian French

Translatable elements withing the application include labels, buttons, tooltips, menu items, messages, and system base data such as statuses, categories, types, etc.

Language selection

Each user has a default language defined in a user property. This property can be set on the user administration screen.

Translation Administration and Custom Languages

The translation screen allows users to view translations for all languages.

It is possible to create and edit translations for any custom screens and to create new custom languages to override system translations if desired.

Culture and Localised Formats

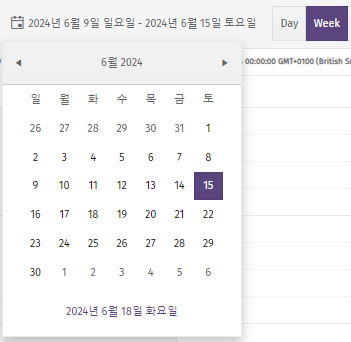

Changing the user language also changes the culture setting, which affects the date format, number format (i.e. decimal point and grouping), week start day, etc.

Examples of number formats

English UK (En-GB)

Danish (Da-DK)

Examples of date formats

English UK (En-GB)

Danish (Da-DK)

Korean (Ko-KR)