Eyelit MES AI Assistant

The latest release of Eyelit MES introduces a powerful AI Assistant designed to enhance user productivity and streamline daily operations.

This intelligent assistant is integrated into the platform, offering contextual support and guidance as you navigate complex manufacturing processes. The AI Assistant can interpret user queries, provide instant answers, and suggest relevant documentation or actions, reducing the time spent searching for information.

Our public documentation is the primary source used by the AI assistant to find and infer answers to your questions. We are continually adding to our public documentation which will improve the quality of responses over time.

The “Ask Eyelit AI” button is displayed at the bottom of every page on the platform.

Electronic Control History Record (eCHR)

We continue to build the eCHR capability to include an increasing library of content that you can store out of the box.

Manage Transaction Controls

What transactions are allowed to be performed on an item depending on its eCHR status. It stipulates if you are permitted to do the transaction if the eCHR hasn’t been signed off. For detailed information, see the section on Manage Transaction Controls in the eCHR Profiles documentation.

eCHR Transfer

This functionality allows you flexibility in how to handle an eCHR where an item/batch on the eCHR is split, i.e., specify if the new item is to be tracked on the same eCHR or a separate one. If necessary, a copy of the existing eCHR can be created at the time of the split. The split item's eCHR, containing all prior history, will continue to be updated from that point onward.

For example, if you’re working on a batch of 100, but then decide you want to rework 10 of the hundred and you want to split the batch, you might want the data of the 10 to be on a different eCHR.

Material split with a new serial number gets its own eCHR

You can have more than one item with the same serial number on one eCHR (as they have shared history) but when you split this item and generate a new item with a new serial number you need to determine if this new item can be tracked on the same eCHR or requires a separate eCHR (as describe above).

For example, you start working on a batch and then split it into serialised items later. So the batch ID is XYZ and split it into item 1, item 2 and item 3. You either want each item to remain on the same batch eCHR, or when you split it off, you each item to have its own eCHR.

When Force eCHR transfer on serial number change is turned on, and if splitting an item results in the new item getting a new visual serial number, then the new item also gets its own eCHR.

Comments against eSignatures

A reviewer of the eCHR can leave a comment which will be recorded against their eSignature. You can view the comment on the eCHR History screen via the eCHR Listing screen. By default, the Signature Comment column is hidden. The eSignature comment is also displayed in the printable eCHR final report.

Clear display of changes to visual serial number (VSN) in eCHR

Where a change in the VSN does not result in a new eCHR, the change in the VSN is clearly displayed in the item’s eCHR summary and details grid.

Report title is user defined

The text in the Printable Report Title field in the eCHR Profile Version screen displays as the printable report title.

HTML Printable Report

Customer logo on printable report

It’s now possible for you to configure your company logo to display at the top of your printable eCHR report. This configuration is done on the Application Properties screen.

Logo displayed on eCHR printable report

Grouping of sub-sections

By default the eCHR listing is grouped by section and ordered timestamp for each record.

It may be useful to add a further grouping to make the report more user friendly, e.g., group all records by operation number. This additional grouping can be defined in the Sub Section Content field.

Note: Configuration of eCHR sections and line types is currently managed through services support. A services representative will assist you with the configuration of this part of the eCHR Profile.

Signature details added to eCHR printable report

Signature details containing author, meaning, timestamp and comments are included in the printable report.

Display secondary approver for Check Result Set Line Type

The details of the secondary approval for a check results set are displayed. The full name and timestamp are displayed in the eCHR details section for the check results set recorded.

Issues

Issue tracking was enhanced in this release. When a lot has an issue associated with it, you can easily find the parent items that have consumed that lot. Similarly, from the perspective of the parent item, you can see the child items that have issues against them.

When the Include Child Item Issues checkbox is checked in the Item Status, Issues view for the parent item, it shows the issues for the child items that were consumed into the parent item.

When you find an item with an issue that has been consumed, you can quickly find all the items to which it’s been consumed.

Material Scrap

Improved handling of child material during WIP scrap

When recording scrap of a WIP item, it accounts for any consumed materials that should be included in the scrapped quantity based on first level of BoM only.

You can specify the quantity of the child items to be included in the scrapped qty.

You can exclude child items from being included in the scrapped qty.

If a BoM Slot is not fully consumed the operator will be prompted to provide information about the components as per above. For example, I am making 10 iced cakes and I am halfway through the icing operation. I have iced 5 of them. I need to scrap 1 WIP cake. I need to specify if the cake I am scrapping is already iced (i.e. ,scrap the icing component as well as the base), or not iced (i.e., do not scrap any icing when you scrap the parent).

If the BoM slot for a WIP item is fully fulfilled the operator is not automatically prompted to enter this data. The quantity of the consumed component to scrap with the parent is calculated as a ratio (i.e., if you scrap 20% of the parent, you also scrap 20% of the child). For example, I am making 10 cakes and all have been iced. If I scrap two cakes, I assume that I am scrapping 20% of cake bases and 20% of icing. Note that this can be changed by the operator if required with the new functionality.

Material Transactions

In 9.1, we added WIP Adjust and WIP Scrap. If the transactions have reasons configured against them, the user will be required to provide a reason when the transaction is performed. The system displays Reason Type and Reason dropdowns during WIP Adjust and WIP Scrap transactions. You cannot make a quantity change if no valid reason is selected.

Public API

The APIs continue to be improved in 9.1.

Error handling and retry mechanism for outbound integration log requests

The following improvements have been made:

Better handling of any exception when performing a send/receive Rest API request.

Sufficient details are provided in the system log to aid investigation.

A retry mechanism (3 times, delay 2s each) has been added for failed requests.

Create a material item trigger type in Integration Manager

You can configure an integration log for inbound Material Item endpoint calls (adjust, move, receive and release). This makes it possible to see integration logs for all inbound material item endpoint calls.

Maintenance Plan

The Maintenance Plan API lets you configure tool calibration and maintenance dates via integration.

Skills API added to integration manager

The Skills/Upsert API is available to be set up in the integration manager.

Improved management of upsert on Unique fields

The logic for upserts work as follows:

If an ID is provided, then always update (and error if not found).

If no ID is provided, then update if the unique field(s) resolve to an existing entity, else create the entity.

This has been applied to the following endpoints in 9.1:

/api/Product/Upsert

/api/ProductType/Upsert

/api/Schedule/Upsert

/api/Tool/Upsert

/api/WorkCentre/Upsert

/api/WorkCentreGroup/Upsert

/api/BOM/Upsert

Job Op Plan endpoint enhancement

The PUT /api/JobOperationPlan/Update endpoint has been enhanced and now supports the setting of a planned work centre.

Public API and New Integration Trigger for Tool Maintenance settings

It is possible to configure tool calibration and maintenance dates via integration.

Workflow Version List

You can obtain a workflow version list via the Public API. The response also contains the workflow version (major and minor), workflow name and workflow SUID.

Quality

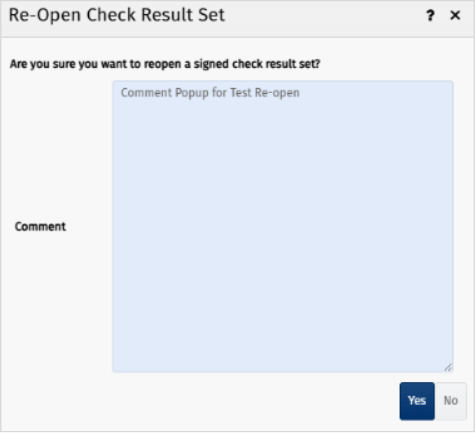

It is now mandatory to provide a reason when reopening an eSigned check result set.

Reporting

The following reports were enhanced:

Work Centre Actual vs Standard report includes Performance %, where:

Performance % = act run time / std time * 100

Added fields to the Labour Performance, Actual vs Standard Analysis report. The report can now be filtered by shift (new), team, works order, department (new), line config (new), user group, product, work order and time.

The Reasons Type field was added to the Inventory Transaction Log and Scrap Transaction Log reports. The Reason field is now filtered based on the Reason Type selected. You cannot select a Reason before selecting the Reason Type, although you can choose Select All Reason Types which will make all Reasons available for selection.

Both OEE (Overall Equipment Effectiveness) and TEEP (Total Equipment Effective Performance) reports can be produced for an asset.

Checklists menu item now includes the following columns: Last Edit Date, Last Edit User, Approved Date.

Created the Production Volume Variance Analysis report. It reports against products that you typically over and under complete. You can easily see where you have large variance against your target volumes and provide details of over or under completion.

The Scrap Analysis report now includes labour time lost due to scrap.

Test Plans

In 9.1, Test Plan Manager underwent several performance and UI improvements.

Tooling

Added a checkbox in Tool Status to Allow Use

The Allow Use was added for Tool Statuses which allows you to choose whether tools in the specified status can be used. By default, this checkbox is ticked.

Tools that are in a status that does not allow use are removed from the dropdown options in a workflow action.

Tool assignment to locations

A Tool Type can be stored in a specified warehouse or set of locations (e.g. work centre locations).

In some cases this can also control whether a tool can be used against a workflow action (e.g. if the tool must be in the correct work centre location).

The location mode options for Tool Types are:

Do Not Filter: Can be stored in any location.

Warehouse: Restricted to locations within a designated warehouse.

Location: Allows you to specify one or more locations for the tool to be located in. Note that some of these locations may only be able to have one tool of a type stored there at any one time, e.g., in a moulding machine you can only have one mould tool located in the machine at any one time. This restriction can be configured at a location level by selecting the Tool Type, clicking Location and then assigning locations / setting restriction as needed.

Previously a tool use action could only be configured to manage a single tool requirement. Tool use actions can now be configured to manage multiple tool requirements.

You can have multiple Maintenance Plans set against a tool or a work centre and it can be controlled that if it’s out of its maintenance schedule, you can’t use it.

Maintenance plans can be configured with a time based logic for both tools and work centres (e.g., must be done every 4 weeks) or use based logic for tools (e.g., must be calibrated every 50 uses).

The Maintenance Management screen has been built which:

Displays maintenance plans.

Shows you a summary of status vs maintenance plan, i.e., time remaining for time based and uses remaining for use based, with highlights for those within warning limits or overdue.

Allows you to record maintenance completion.

Provides a history of maintenance.

The new Allow Use condition enables temporary override of set limits for maintenance or calibration, allowing continued tool use for the current cycle. For example, if calibration is due during a job, Allow Use can permit continued use of the tool until the job is finished.

Manual Tool Use action configuration updates for multiple tool requirements.

Workstation

Where there are many workflow tasks that could be triggered for a given item, the New Task button in the workstation brings up a list of all workflow tasks. In 9.1, the New Workflow Task pop-up was enhanced to filter available tasks based on Workflow Type.